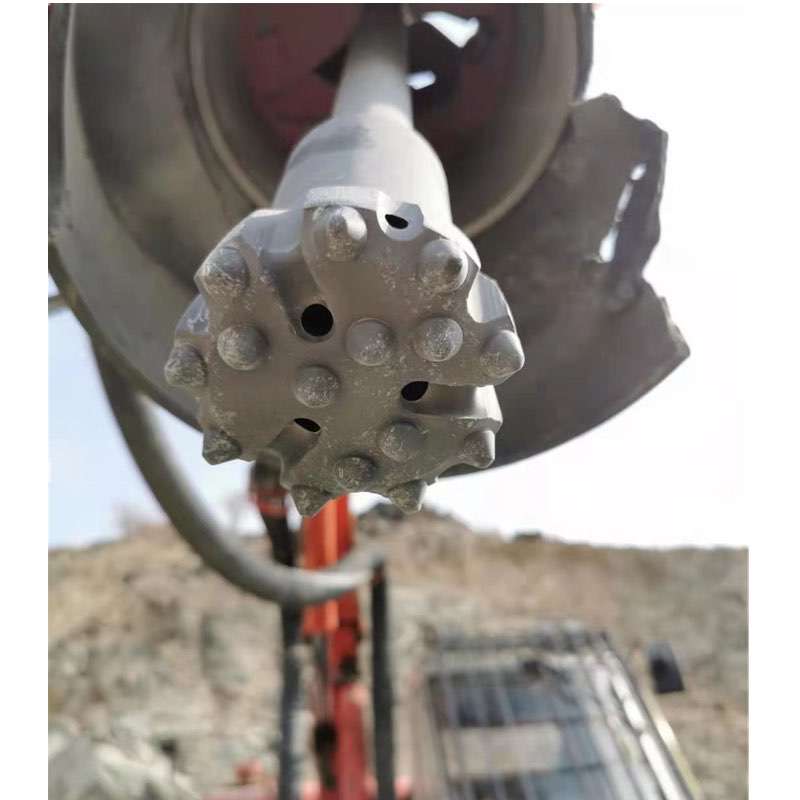

Rock Drill Bits R25

Durability: Tungsten carbide tips resist wear in hard rock and abrasive conditions.

Versatility: Multiple sizes (R-series for lighter rigs, T-series for heavy-duty) suit varied drilling depths and rock hardness.

Efficiency: Optimized designs reduce energy consumption while maximizing penetration rates.

Cost-Effective: Interchangeable and easy to replace, lowering long-term operational costs.

R25 Rock Drill Bits offer versatile, high-performance solutions for diverse drilling needs. Built with tungsten carbide tips, they ensure durability in hard rock and abrasive conditions. Ideal for mining, quarrying, tunneling, and construction, these bits adapt to handheld, pneumatic, and hydraulic rigs. Threaded connections simplify installation, while optimized designs boost penetration rates, minimize wear, and enhance productivity.

Product Specification:

Product | Dia | Button size | Gauge Button Angle | Flushing hole | Weight | |||

(mm) | (inch) | Gauge No Size | Front No Size | Side | Front | (kg) | ||

| (mm) | (mm) | |||||||

R25 (1″) General Flat Face Button Bit | 35 | 1 3/8 | 5×8 | 2×7 | 30° | 2 | 1 | 0.4 |

35° | 0.3 | |||||||

38 | 1 1/2 | 5×8 | 2×8 | 30° | 2 | 1 | 0.5 | |

2×8 | 35° | 0.4 | ||||||

5×9 | 2×7 | 30° | 2 | 1 | 0.6 | |||

2×7 | 35° | 0.5 | ||||||

41 | 1 5/8 | 5×9 | 2×8 | 30° | 1 | 1 | 0.5 | |

35° | 0.4 | |||||||

43 | 1 11/16 | 5×9 | 2×9 | 30° | 2 | 1 | 0.6 | |

35° | 0.5 | |||||||

45 | 1 3/4 | 5×9 | 2×9 | 30° | 1 | 1 | 0.6 | |

35° | 0.5 | |||||||

R25 (1″) Retract Flat Button Bit | 45 | 1 3/4 | 6×9 | 3×8 | 30° | 1 | 3 | 1 |

35° | 0.9 | |||||||

51 | 2 | 6×10 | 3×9 | 30° | 1 | 3 | 1.4 | |

35° | 1.3 | |||||||

57 | 2 1/4 | 6×10 | 3×10 | 30° | 0 | 3 | 1.6 | |

35° | 1 | 3 | 1.5 | |||||

Functions:

1. Penetrate hard rock, concrete, and compacted formations.

2. Compatible with dry/dust-flush or wet/mud-flush systems.

3. Threaded connections (R/T-series) ensure secure rig attachment.

4. Transfer impact energy effectively for consistent performance.

Usage Methods:

1. Match bit size (R25, T51, etc.) to rig specifications.

2. Securely thread the bit into the drill rod or chuck.

3. Adjust drilling parameters (air pressure, RPM) based on rock hardness.

4. Regularly flush debris to prevent jamming and overheating.

Application Fields:

1. Mining & Quarrying: Blast hole drilling, ore extraction.

2. Construction: Tunneling, foundation anchoring, roadwork.

3. Geotechnical Engineering: Soil/rock sampling, slope stabilization.

4. Utilities: Water well drilling, pipeline installations.

Precautions:

1. Ensure thread compatibility (R/T-series) with drill rods/rigs.

2. Avoid excessive force to prevent bit shank damage.

3. Inspect for cracks or tip erosion before use.

4. Use proper PPE (goggles, gloves) during handling.

Applicable Rigs:

R25/R28/R32: Handheld pneumatic drills, light jackleg rigs, small surface drills.

T38/T45/T51: Hydraulic top-hammer rigs, crawler drills, deep-hole rotary/blast hole rigs.

WHATSAPP

WHATSAPP