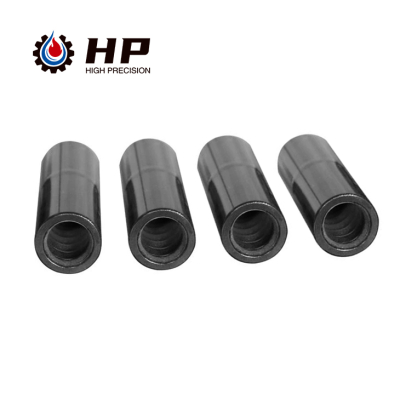

Drifter Drill Rod

Drifter drill rods play a crucial role in drilling equipment for a wide range of mining, quarrying, and construction tasks. They are frequently utilized in geological surveys, surface and underground mining activities, as well as tunneling projects.

Drifter drill rods come in a variety of sizes and specifications tailored to meet the specific needs of different drilling operations. The standard sizes include 22mm, 25mm, and 28mm, with lengths varying from 800mm to 6000mm. The inner hole diameter of the drill rods falls within the range of 11mm to 19mm.

Functions: Drifter drill rods serve the crucial purpose of transmitting power from the drilling rig to the drill bit. Their hollow construction enables debris flushing and allows for the introduction of compressed air or water to aid in the drilling process. Known for their high strength and wear resistance, these rods are built to withstand challenging drilling conditions and deliver enduring performance.

Features: Crafted from top-grade steel and subjected to heat treatment, Drifter drill rods boast exceptional durability and strength. Equipped with a threaded connection for easy attachment to both the drilling rig and drill bits, they feature a smooth surface finish that reduces friction, optimizing drilling efficiency.

Specifications: The specifications of Drifter drill rods encompass the rod's diameter, wall thickness, length, and thread type, with high-quality steel being the predominant material used in their production.

Usage methods: Usual practice involves pairing Drifter drill rods with a drilling rig, requiring caution during assembly and disassembly. Regular inspection for signs of wear and tear, along with ensuring the rods are in good condition before utilization, is paramount. Proper lubrication of the thread connections is recommended to prevent damage during operations.

Application fields: Drifter drill rods find widespread application in geological exploration, surface mining, underground mining, and tunneling operations, serving as indispensable components of drilling equipment across diverse mining, quarrying, and construction activities.

Precautions: Adherence to manufacturer specifications for the handling and usage of Drifter drill rods is crucial to prevent damage to the rods, drill bits, and drilling rig. Operators must exercise care, conduct regular inspections, and wear appropriate personal protective equipment to ensure safe and efficient drilling operations.

Applicable drilling rigs: Drifter drill rods are compatible with various drilling rigs, including hydraulic, pneumatic, and electric variants. The choice of drilling rig and drill bit should align with the specific requirements of the drilling operation at hand.

In summary, Drifter drill rods play a pivotal role in diverse mining, quarrying, and construction applications, offering versatility and reliability. With a range of sizes and specifications available, these rods are engineered to withstand rigorous drilling conditions and are well-suited for use across different drilling rigs. By following prescribed guidelines for handling and maintenance, operators can maximize the performance and longevity of Drifter drill rods.

WHATSAPP

WHATSAPP