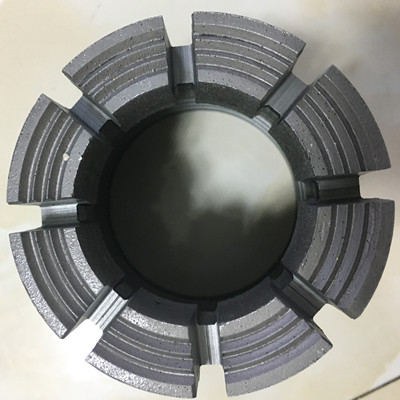

Tricone Serrated Well Drilling Bits Well Drilling Bits

Due to the use of high-quality alloy steel materials and specially treated cutting teeth, the serrated tricone well drill bit can maintain good cutting performance and stability during a long period of high-intensity work, and is not easy to fail or be damaged, thus reducing the frequency of replacement and maintenance costs, and improving the efficiency and economy of drilling operations.

Serrated Tri-Cone Well Drill Bits are made of high quality alloy steel material, usually precision alloyed steel with excellent hardness and wear resistance. This material is able to maintain stable cutting performance under high-intensity working conditions and is not easily deformed or damaged, thus extending the life of the drill bit.

Basic Info.

By keeping the borehole clean, the Serrated Tricone Well Bit is able to maintain a stable working condition, avoiding vibration or unstable drilling process due to clogging. This helps to maintain good contact between the bit and the rock, ensuring effective cutting and drilling efficiency.

Product Parameters

| IADC | WOB (KN/mm) | RPM (r/min) | Applicable Formations |

| 417/437/ 447/415/435 | 0.35~0.9 | 150~70 | Very soft formations with low compressive strength and high drillability, such as clay, mudstone, chalk, gypsum, salt, soft limestone, etc. |

| 517/527/515 | 0.35~1.0 | 140~60 | Soft formations with low compressive strength and high drillability, such as mudstone, gypsum, salt, soft limestone, etc. |

| 537/547/535 | 0.45~1.0 | 120~50 | Soft to medium formations with low compressive strength, such as medium, soft shale, medium soft limestone, medium soft sandstone, medium formation with harder and abrasive interbeds, etc. |

| 617/615 | 0.45~1.1 | 90~50 | Medium hard formation with high compress strength, such as hard shale, limestone, sandstone, dolomite. etc |

| 637/635 | 0.5~1.2 | 80~40 | Hard formations with high compressive strength, such as sandstone, limestone, dolomite ,hard gypsum, marble, etc. |

| Note: The upper limits of WOB and RPM in above table should not be used simultaneously. | |||

| Popular models | |

| size | IADC CODE |

| 4 1/2''(114.3mm) | 115 117 127 217 417 437 517 537 637 |

| 4 3/4''(120.7mm) | 115 117 127 217 417 437 517 537 637 |

| 5 7/8''(149mm) | 115 117 127 217 417 437 517 537 637 |

| 6''(152mm) | 115 117 127 217 417 437 517 537 637 737 |

| 6 1/2''(165mm) | 115 117 127 217 417 437 517 537 617 627 637 737 |

| 7 1/2''(190mm) | 115 117 127 217 417 437 517 537 617 627 637 737 |

| 7 7/8''(200mm) | 115 117 127 217 417 437 517 537 617 627 637 737 837 |

| 8 1/2''(215.9mm) | 115 117 127 217 417 437 517 537 617 627 637 737 837 |

| 8 3/4''(222.3mm) | 115 117 127 217 417 437 517 537 617 627 637 737 837 |

| 9 5/8''(244.5mm) | 115 117 127 217 417 437 517 537 617 627 637 737 837 |

| 9 7/8''(250.8mm) | 115 117 127 137 217 417 437 517 537 617 627 637 737 837 |

| 11 5/8''(295.3mm) | 115 117 127 217 417 437 517 537 617 627 637 737 837 |

| 12 1/4''(311.1mm) | 115 117 127 217 417 437 517 537 617 627 637 737 837 |

| 14 3/4''(374.7mm) | 115 117 127 217 417 437 517 537 617 627 637 737 837 |

| 15 1/2''(393.7mm) | 115 117 127 217 417 437 517 537 617 627 637 737 837 |

| 17 1/2''(444.5mm) | 115 117 127 217 237 417 437 517 537 617 637 |

| 20''(508mm) | 115 117 127 217 237 437 517 537 637 |

| 22''(558.8mm) | 115 117 127 217 437 517 537 637 |

| 24''(509.6mm) | 115 117 127 217 437 517 537 |

WHATSAPP

WHATSAPP