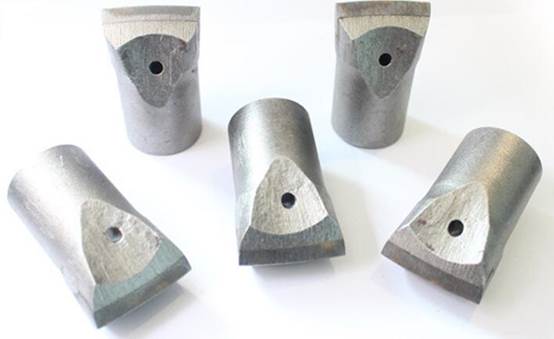

Tapered Chisel Bit

1. Chisel-shaped tip: The chisel-shaped tip concentrates the drilling force to a single point, allowing for efficient rock breaking. It provides a focused impact to penetrate the rock and break it apart.

2. Tapered design: The tapered shape of the bit allows for easy removal of drill cuttings from the hole. As the bit progresses deeper into the rock, the wider part of the taper helps clear the debris and prevents the bit from getting stuck.

3. Material composition: Tapered chisel bits are typically made of hardened steel or cemented carbide. These materials provide durability and resistance to wear and abrasion, allowing the bit to withstand the demanding conditions of rock drilling.

4. Versatility: Tapered chisel bits can be used in various drilling methods, including handheld rock drills and pneumatic/hydraulic drilling machines. They are suitable for a range of rock formations and drilling applications.

Tapered chisel bit is easy to manufacture, easy to resharpen, reliable and adaptable to rock properties. Often with light internal combustion, electric, pneumatic and hydraulic rock drills, in all types of rock drilling holes with a diameter of D50mm or less, suitable for light rock drills drilling hardness is not high in the rock layer. At present, is still China's extractive industry, medium and small diameter rock hole drilling project used by the main varieties of drill bits.

A tapered chisel bit is a type of rock drilling tool commonly used in mining, construction, and geotechnical engineering applications. It is designed to penetrate and break up rock formations during drilling operations.

The tapered chisel bit has a conical shape with a flat chisel-shaped tip. The tip is typically made of hardened steel or cemented carbide, which provides resistance to wear and abrasion. The taper design allows for efficient drilling and easy removal of drill cuttings from the hole.

Tapered chisel bits are usually used with handheld rock drills or pneumatic/hydraulic drilling machines. They are inserted into the drill rod or drill string and secured using a coupling or connector. The drilling machine provides the necessary force and rotation to penetrate the rock formations.

The chisel-shaped tip of the bit is designed to concentrate the drilling force at a single point, allowing for effective rock breaking. The narrow tip also helps to prevent the bit from getting stuck in the hole and facilitates the removal of drill cuttings.

Tapered chisel bits come in various sizes and configurations to suit different drilling requirements and rock formations. The selection of the appropriate bit size and shape depends on factors such as the rock hardness, drilling method, and drilling machine capabilities.

Proper maintenance and regular inspection of tapered chisel bits are important to ensure their optimum performance. This includes monitoring the wear of the tip and replacing the bit when it becomes excessively worn or damaged.

In summary, a tapered chisel bit is a specialized rock drilling tool with a conical shape and a chisel-shaped tip. It is used for efficient rock penetration and breaking during drilling operations. Tapered chisel bits are widely used in the mining, construction, and geotechnical engineering industries.

WHATSAPP

WHATSAPP