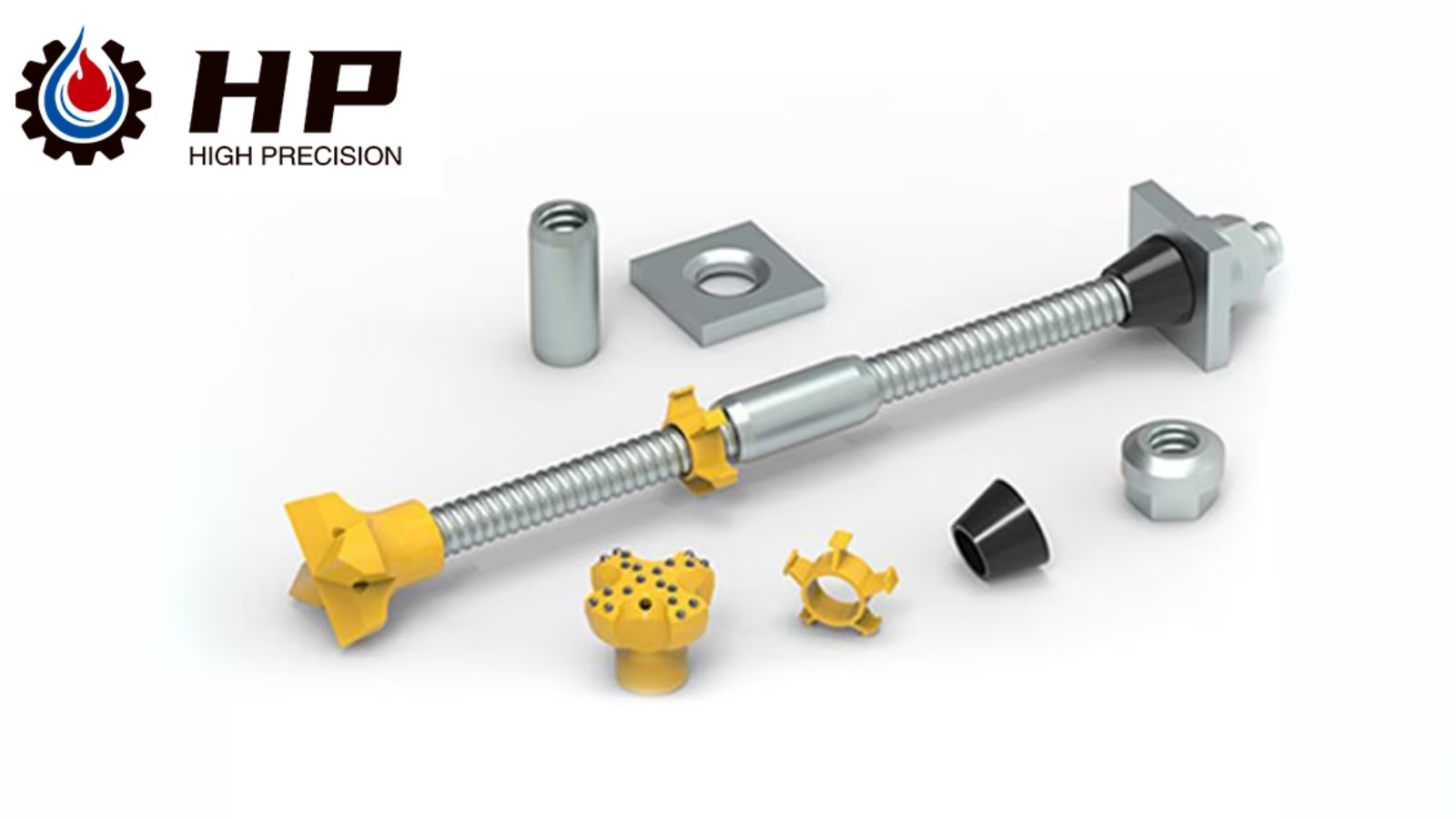

Hollow Threaded Bar

Integrated Drilling & Anchoring: Combines drilling, grouting, and anchoring in one step, saving time and labor.

High Load Capacity: R-thread design ensures efficient load transfer and resistance to pull-out forces.

Corrosion Resistance: Often galvanized or epoxy-coated for durability in harsh environments.

Versatility: Suitable for unstable soils, fractured rock, and water-bearing strata.

Cost-Efficiency: Eliminates need for separate drilling equipment and casing.

The Self-Drilling Anchor Hollow Bar R Thread System integrates drilling, grouting, and anchoring into a single streamlined process, ideal for stabilizing unstable soils and fractured rock. Its corrosion-resistant R-thread design ensures high load capacity and durability, while compatibility with hydraulic or handheld rigs enables efficient use in slope stabilization, tunneling, mining, and emergency repairs.

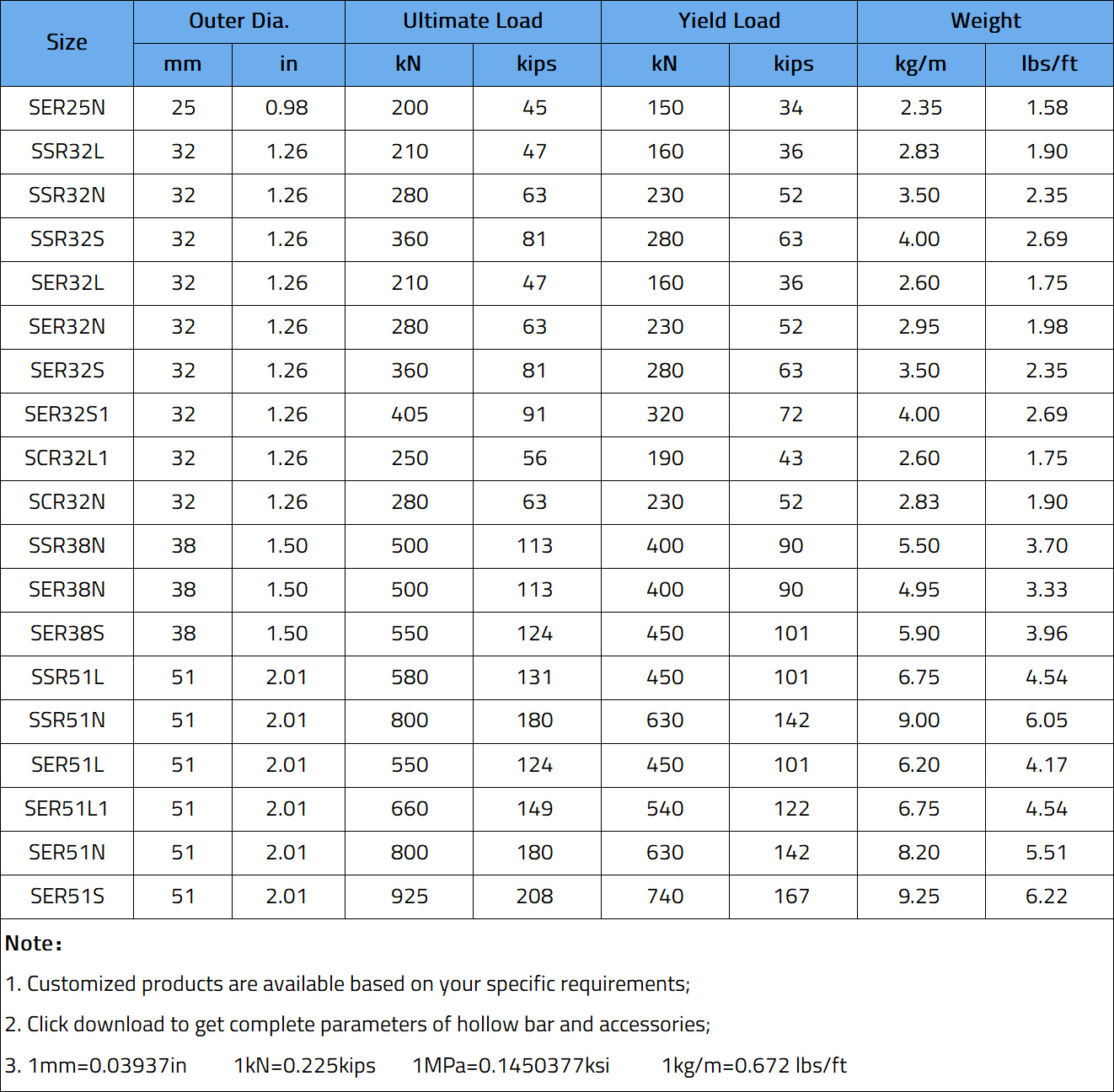

Product Specifications:

Functions:

Acts as a drill bit, anchor rod, and grout conduit simultaneously.

Transfers structural loads to stable geological layers.

Stabilizes loose or weak ground through grout injection.

Compatible with nuts, plates, and couplers for modular installations.

Usage Methods:

Select R-thread bolt diameter/length based on ground conditions and load requirements.

Attach to a rotary drill rig; drill to desired depth while rotating and flushing with air/water.

Inject grout through the hollow bolt during/after drilling for soil reinforcement.

Install bearing plates and tighten nuts to secure the anchor.

Monitor torque and alignment to prevent bending or thread damage.

Application Fields:

Slope Stabilization: Prevents landslides in highways, railways, and mining sites.

Tunneling & Underground Construction: Supports roofs/walls in soft ground or rock.

Mining: Reinforces stopes and tunnels in unstable strata.

Foundation Engineering: Anchors retaining walls, dams, and deep excavations.

Emergency Repairs: Rapid stabilization of collapsed structures.

Precautions:

Ensure compatibility between bolt diameter, thread type (R-thread), and drill rig specifications.

Avoid over-torquing during installation to prevent thread stripping.

Inspect bolts for damage or blockages before grouting.

Use PPE during drilling/grouting to avoid exposure to debris/chemicals.

Store bolts in dry conditions to prevent pre-installation corrosion.

Applicable Rigs:

Hydraulic rotary drill rigs with high torque/RPM capabilities.

Crawler-mounted rigs for steep or uneven terrain.

Handheld pneumatic drills (for smaller R-thread bolts in confined spaces).

Multi-functional rigs with grout injection systems.

WHATSAPP

WHATSAPP